Thomas Zimmermann (Product Manager Photovoltaics)

"With LHS, module performance can be increased by up to 3%."

Mr. Zimmermann, you are the Product Manager of Photovoltaics, a technology in which light energy is directly transformed into electrical energy using solar cells.

In which areas of photovoltaics is Carl Schlenk AG active and since when?

SCHLENK has been a reliable partner of the photovoltaic industry for 25 years. We produce tinned strips that are used in both thin-film and crystalline modules.

These contact strips are soldered and connect the individual solar cells with each other so that the generated electricity can be transported.

Over the past months we have succeeded in developing a new cell connector, LHS for short, which can significantly increase module performance.

What exactly does LHS mean and how can this cell connector increase the effectiveness of the photovoltaic modules?

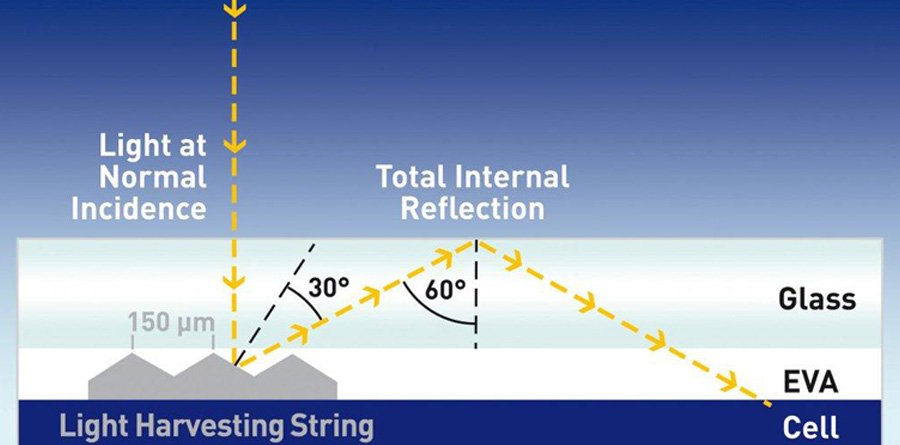

LHS means Light Harvesting String. LHS offers solar module builders a huge advantage because the connectors that were previously used shade the active cell surfaces. The LHS connector is equipped with a precisely structured silver surface. This reflects the light from the connector to the boundary layer between air/glass and then back to the cell. This total internal reflection (TIR) makes it possible to use up to 90% of the shaded surface for generating electricity. In this way, module performance can be increased by up to 3%.

Mr. Zimmermann, using LHS to effect a 3% increase in the level of efficiency of the modules is huge! Does that also mean higher costs or even a need for new production plants?

No, just the opposite. With our LHS SELECT product family, we have developed a cell connector that is selectively pre-tinned in the areas in which the cells are connected. In this way, it is cost-effective to integrate this unique connection technology into existing production processes with just a few adaptations.

Are there competing technologies and, if so, what are the advantages of LHS SELECT in comparison?

Currently, an increase in performance similar to that with LHS can only be achieved with special cells, the so-called rear contact cells. These cells do not have any connectors on the "sunny side", but are more expensive than conventional solar cells. In addition, suitable production plants are required for using these cells, so this alternative is significantly more expensive.

Other advantages of the LHS include the following:

Increased module performance, designed for immediate use, lower rate of cell breakage, available in a wide variety of dimensions, optimum electrical conductivity, high quality appearance.

What is your assessment of the development of photovoltaic technology and the photovoltaic market in the coming years?

Reductions in subsidies will lead to even more consolidation in the industry in the next few years. However, over the long term we continue to see the solar field as a growth market. Due to the limited size of roof surfaces, in the future "high performance modules" will become a focus of interest. Our LHS connectors, which increase efficiency, are well-suited for this development.

And who are the contact persons for those interested in this application?

They can contact Mr. Thomas Booz, Head of Product Development / Application Technology or contact me, the Product Manager of Photovoltaics, directly.