Powder metallurgy / Sinter technology

Copper and copper alloy powder, copper powder, bronze powder, brass powder

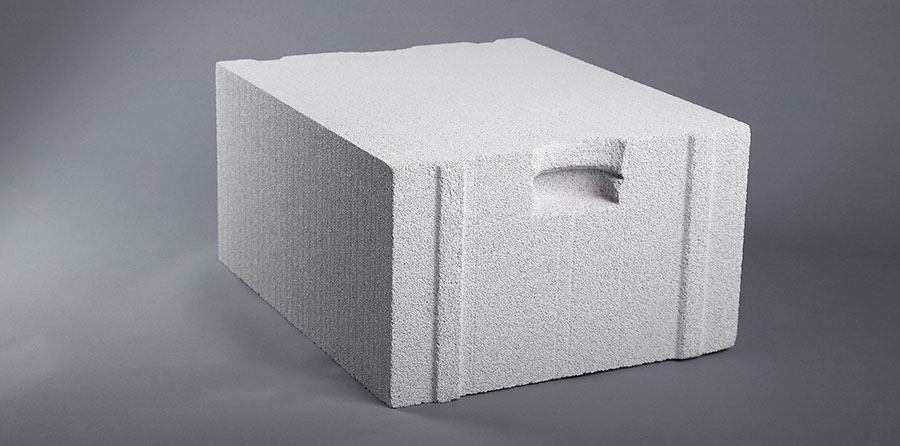

The powder metallurgy processes for manufacturing metallic parts include forming, compression and the following sintering process as well as subsequent calibration processes to optimize dimensional accuracy, if required.

Typical forming processes are pressing, pouring and the unpressurized application of powder across the surface. Other specialized processes include laser generation, metal injection molding (MIM), and 3D printing, among others. Typical sintered products include metallic molded parts, used primarily in the automobile industry (e.g. bearings and bearing shells, sliding bearings, components for motors and gearboxes), filters and brake linings and tool parts (e.g. diamond tools).