Materials industry

Copper and copper alloy powder, copper powder, bronze powder, brass powder

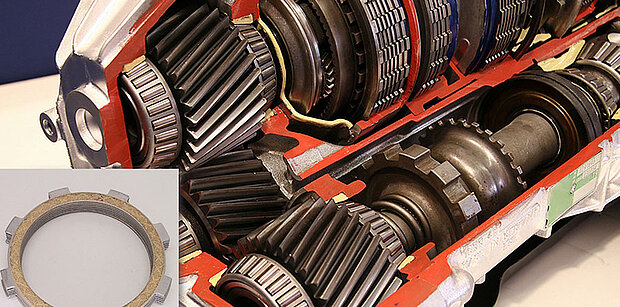

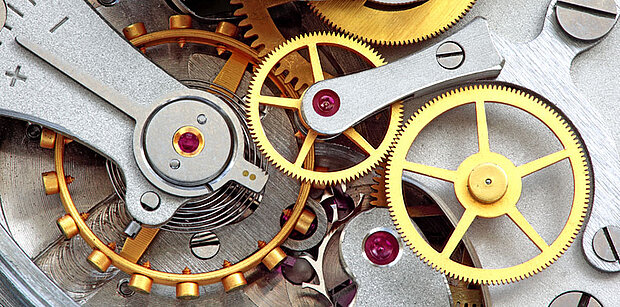

The field of powder metallurgy and the metallic materials it generates comprise a wide spectrum of metals and alloys as well as end uses and technologies.

Due to consistent expansion in the area of metallic materials, with a specific focus on air atomized copper and copper alloy powders, SCHLENK is now one of the leading providers in target markets such as bearing materials, friction and brake linings, contact materials and PTFE-bound compounds as well as in niche markets such as soldering technology and diamond tools, among others.

The portfolio is complemented by the Rogal® Select series. These inert gas atomized, high-purity copper powders are specifically engineered for use in demanding additive manufacturing processes and industrial 3D printing.

Service orientation, consistency in compliance with the required quality criteria and expert technical application service form a foundation for success.

Technical plastics and compounds

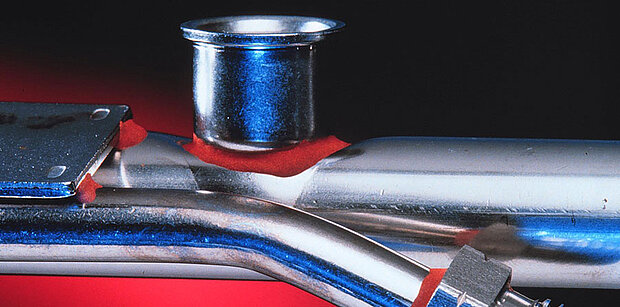

Due to its outstanding wear resistance and tribological properties, PTFE is used as a sliding material (e.g. in bearings) and in seals. In combination with copper or bronze powders as technical compounds, their density, strength and thermal conductivity are improved significantly.

Additive Manufacturing

The Rogal® Select series offers high-purity copper powders engineered for additive manufacturing processes like Laser Powder Bed Fusion, Cold Gas Spray, and Directed Energy Deposition. With outstanding conductivity, excellent flowability, and reliable process stability, they are ideal for high-performance applications in aerospace, automotive, and power electronics.