SCHLENK Metal Foils

SCHLENK Metal Foils specializes in manufacturing extremely thin foils.

Areas:

Material

Surfaces

Foil and strip delivery options

Processing

Possible applications of these non ferrous metal foils are multiplied by surface finishing, and the metallic compound of metal foils. Reduced material input, flexible applicability and better handling: the metal foils of Schlenk meet the demand of many industries for reduced material input. They support the development of smaller, lighter and high-performing products and preserve the environment by saving resources.

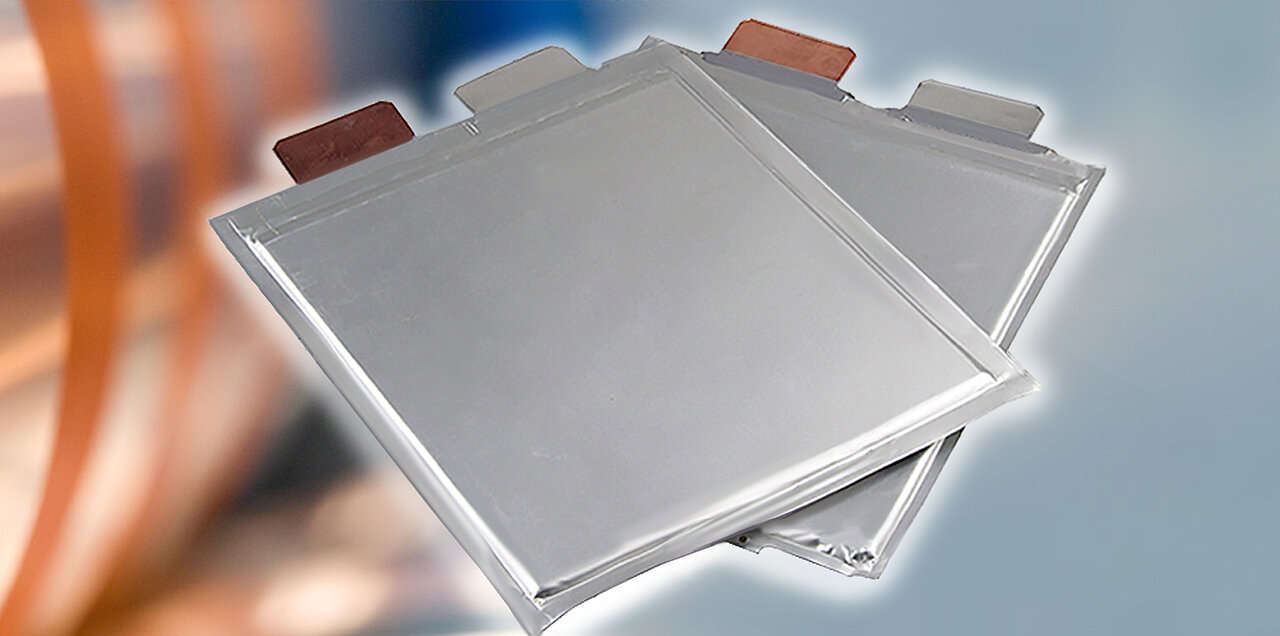

The wide range of applications extends from photovoltaic solar modules, lithium-ion batteries, special batteries, heat exchangers, surface finishing, fuses, capacitors, transformers, electronics, medical technology, flexible printed circuit boards, all the way to special cables and flexible flat cables for state-of-the-art automobile technology.

Basic production data:

Flexibility is important to us: within these basic dimensions, we can offer you a wide range of combinations of thicknesses and widths.

- Minimum thickness: 6 µm

- Maximum width: 660 mm

- Average thickness in annual production: 29 µm

We use a variety of technologies and equipment to manufacture our special foils. For example:

- Rolling machinery (including a 20 roll rolling mill)

- slitting machinery

- Ovens for annealing

Material

SCHLENK Metal Foils is highly specialized in cold rolling. Primarily, we produce very thin foils and strips from non-ferrous metals.

Available Materials:

Copper Brass Tombak Bronze Silver Nickel

Nickel-Silver Copper-nickel

Roll-clad composites

Surfaces

The surfaces of our foils and strips form the interfaces between our customers and their applications.

Whether in combinations of different materials in a roll-cladding process or in physical or chemical processing: targeted surface design is becoming more and more important with regard to technical products in order to meet high quality requirements and to implement new or additional features.

Schlenk Metallfolien has been meeting these challenges head on for many years now. Thanks to targeted investments in plant technology and expertise, we can realize your ideas with regard to surface design.

Finish and surface versions

The physical and electrical properties alone of untreated, non-ferrous metals do not meet the requirements for some applications. Thanks to our technology, we can adapt most material surfaces so that even the most demanding projects can be realized.

Besides standard foil surfaces we offer the following surface adaptations and versions:

- High gloss surfaces (RA <0.1 µm)

- Matte surfaces

- Degreased surfaces (For more information, see Degreasing)

- Passivated surfaces, with either organic or inorganic surface protection

- Smooth coating for nickel

![[Translate to English:] Ausführungen [Translate to English:] Oberflächenbehandlungen, metallischen Verbund von Metallfolien, Solarmodulen, Lithium-Ion Batterien, Automobiltechnik, folien, spulen, ringe, rollen, bänder, reel-to-reel verfahren](/fileadmin/_processed_/9/c/csm_t_ausfuehrungen_e87ac238cc.jpg)

Foil and strip delivery options

Foils and strips by Schlenk Metallfolien are used in a wide variety of products and applications. In order to meet the various requirements, we use a wide variety of processing equipment and machinery.

We offer options for your processing needs should it be for reel-to-reel technology or for piece by piece manufacturing.

Our options for various delivery versions include:

- Sheets

- Coils, wide or narrow

- Spools

- Rings

Sheets

We can provide almost any of the dimensions offered in our production program as sheet sections as well.

- Sheets cut from strips, untrimmed

- Sheets delivered as raw goods or layered with intermediate paper

Thanks to our specialized partners, we can also implement initial processing requested by our customers, including the following:

- Punching

- Cut to form

- Labeled

Coils, spools, rings

Thanks to our wide variety of equipment and machinery, from our master coils we can produce all types of coils, spools and rings. The rings and spools can weigh anywhere from one hundred grams to several tons. The maximum weight per unit depends on the dimensions.

Our in-house definitions of coils, spools and rings are as follows:

Coils:

- The strip / foil width is greater than the wound diameter.

- The coils are available on steel, cardboard and plastic cores.

Rings:

- The rings consist of sections of rolls or narrowly cut foils and strips.

- In general, the strip / foil width is significantly less than the wound diameter.

- We also offer the special so-called film spool for strip widths of less than 10 mm. Film spools are special cores with supporting, protecting side shields.

Spools:

- We provide narrowly cut foils and strips on traverse wound spools.

- The advantage of spooled foils and strips are long lengths at relatively small external diameters.

Processing

Slitting, rolling and annealing are among the processing steps in the production of our special foil products.

Our expertise is founded on the processing of materials.

SCHLENK offers foil products or sub-contracting with regard to your special materials: Benefit from our expertise and processing technologies!

Sub-contracting and contract manufacturing

We specialize in the production of very thin special metal foils. Thanks to our wide variety of equipment and machinery, we can also provide capacity for sub-contracting and contract manufacturing.

These are the technologies we can provide for you:

- Rolling

- Slitting

- Rewinding

- Traverse winding on spools

- Special degreasing

- Flexible conditions for sub-contracting. By request, we would be happy to check on the conditions for your needs.

As an experienced manufacturer of very thin foils, we have successfully processed the following materials for customer orders:

- C155 (special copper alloy)

- K88 (precipitation hardening special copper alloy)

- Gold

- Platinum

- Magnifer (soft-magnetic nickel-iron alloy)

- Stainless steel

... and much more.

If you need additional processing options, please contact us and we can check on possibilities for realization with our equipment and machinery.